5 Axis CNC Router Fast Machining High Efficiency

- Model: AC-1212-5 Axis-TABLE

- Working Size: 1200*1200*800MM

- Price Range: $35000.00 to $99500.00 / Set based on the configuration

- Spindle: 10KW HITECO

- Table: Vacuum Table with Gantry Move

- Payment Terms: T/T(Telegraphic Transfer), Visa, Mastercard, American Express, and Discover cards

- Warranty: 2 Years

- Supply Ability: 30 Sets / Month

Description of 5 Axis CNC Router Fast Machining High Efficiency

The 5 Axis CNC Router for Fast Machining is designed for manufacturers who demand high-speed, high-precision machining for complex 3D parts. With simultaneous five-axis movement and advanced RTCP control, this machine delivers multi-angle cutting, undercutting, and intricate surface milling with remarkable accuracy and speed. Its rigid heavy-duty frame, premium servo motors, and high-performance spindle ensure stable operations, reduced vibration, and superior surface finish, even during long production runs.

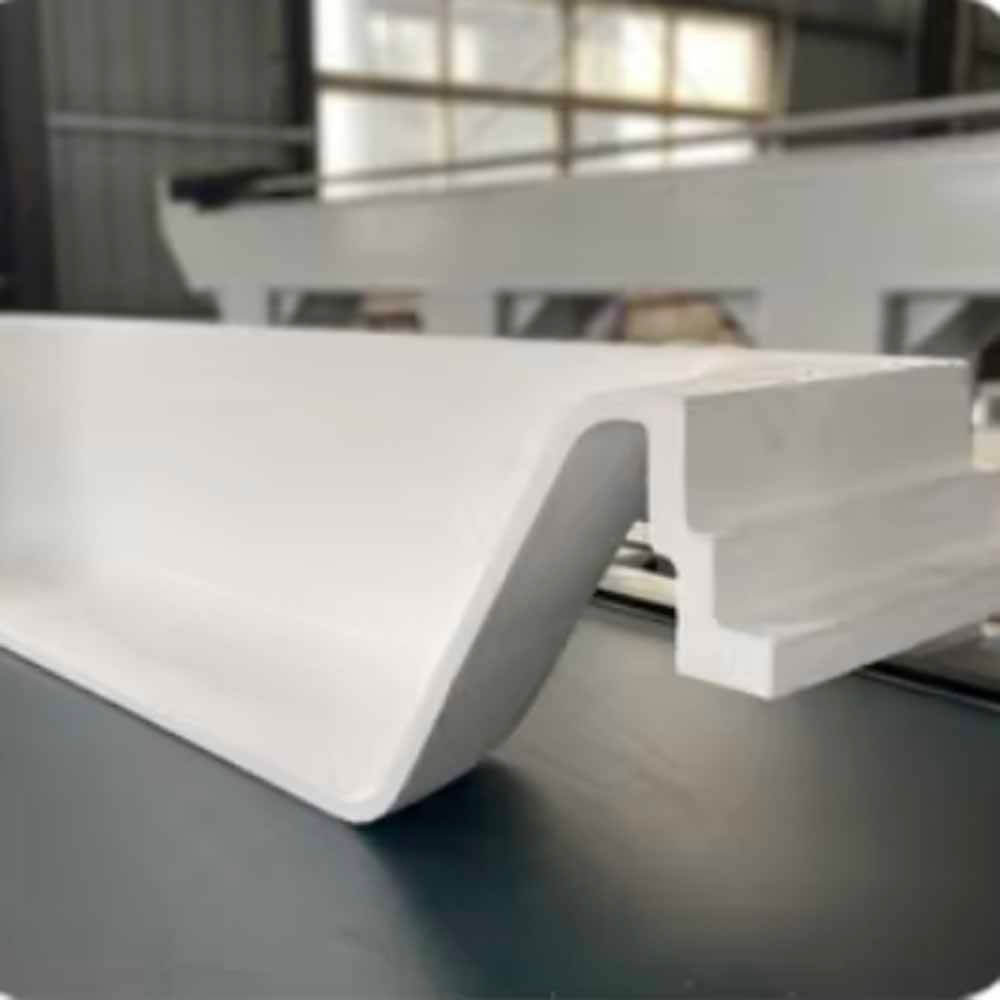

Ideal for furniture manufacturing, mold making, aerospace components, automotive prototypes, signage, and composite material processing, this CNC router maximizes efficiency by reducing manual labor and production time while maintaining tight tolerances. Compatible with a wide range of materials—including wood, MDF, foam, plastics, acrylic, aluminum, and carbon fiber composites—it offers versatile and reliable performance for high-volume production and complex part machining.

Features of 5 Axis CNC Router Fast Machining High Efficiency

- 5-Axis Linkage System – Supports RTCP (Rotating Tool Center Point), simultaneous five-axis interpolation, enabling multi-angle cutting, undercutting, and high-speed machining with exceptional precision.

- Versatile Wood & Plastic Processing – Perfect for edge trimming, sawing, profiling, polishing, carving, bending wood furniture components, and processing powder-coated surfaces, ensuring superior finishing quality.

- Professional Customer Training – Our experienced training team provides comprehensive guidance to ensure customers can operate the machine confidently and efficiently.

- Live Customer Demonstrations – Our factory offers on-site processing demonstrations, allowing users to see real-time machining results and understand machine capabilities.

- High-Speed Spindle & Motor System – Equipped with premium servo motors and high-performance spindle for fast acceleration, smooth motion, and reduced vibration, maximizing efficiency.

- Rigid Heavy-Duty Structure – Strong welded steel frame with heat-treated reinforcement ensures long-term stability, minimal deflection, and precise machining even during high-speed operations.

- Multi-Material Capability – Suitable for wood, MDF, acrylic, foam, plastics, aluminum, and composite materials, allowing versatile applications across industries.

- User-Friendly Control System – Advanced CNC controller with intuitive interface supports G-code, CAD/CAM software compatibility, and easy programming, simplifying complex operations.

- Automatic Tool Change & Positioning – Optional ATC (Automatic Tool Changer) improves production efficiency and reduces downtime for continuous high-volume machining.

- Dust Collection & Safety System – Integrated vacuum table and dust extraction system maintain a clean working environment, protecting both the operator and machine longevity.

Specification of 5 Axis CNC Router Fast Machining High Efficiency

| No. | Item | Specification |

|---|---|---|

| 1 | Model | AC-1212 5-Axis CNC Router |

| 2 | Movement Type | Table-Moving Configuration |

| 3 | Machining Area (X×Y×Z) | 1200 × 1200 × 800 mm |

| 4 | Rotary Axis Travel | A-axis ±120°, C-axis ±213° |

| 5 | Double Pendulum Head | HS300 |

| 6 | Pendulum Head Manufacturer | HSD (Italy) |

| 7 | Spindle Power | 7 kW |

| 8 | Spindle Speed | Up to 20,000 RPM |

| 9 | Table Dimensions | 1200 × 1200 mm |

| 10 | Table Material | Cast Steel |

| 11 | Workpiece Fixing Type | T-Slot Table |

| 12 | Operator Training Requirement | Minimum 2 weeks |

| 13 | Machine Overall Size (L×W×H) | 2500 × 3000 × 2500 mm |

| 14 | Total Machine Weight | 8,000 kg (8T) |

| 15 | Operating Voltage | AC 380V, 3-Phase, 50Hz |

| 16 | File Conversion Efficiency | 0.5 hr/day |

| 17 | File Transfer Method | USB Port |

| 18 | Data Storage & Capacity | USB, CF card, cable transmission |

| 19 | Maximum Axis Speeds | X/Y: 40 m/min, Z: 20 m/min, A/C: 2700°/min |

Application of 5 Axis CNC Router Fast Machining High Efficiency

The 5-Axis CNC Router is widely used across multiple industries due to its precision, versatility, and ability to handle complex 3D geometries.

- Mold & Pattern Making – Ideal for crafting wood, wax, gypsum, foam, and composite molds, including prototypes, industrial molds, casting patterns, and intricate model designs for automotive, aerospace, and consumer products.

- Furniture Manufacturing – Perfect for producing wooden doors, cabinets, panels, office furniture, tables, chairs, stair components, and custom doors & windows, allowing for intricate carvings, 3D contours, and mass production of high-quality furniture pieces.

- Wood Product Fabrication – Suitable for musical instrument components, gaming cabinets, computer desks, sewing machine tables, and specialty wooden products, ensuring high accuracy and consistency for detailed woodworking projects.

- Panel & Plate Processing – Handles insulation components, plastic and chemical parts, PCB boards, automotive interior panels, bowling lanes, stair treads, epoxy resin parts, ABS, PP, PE, and carbon fiber reinforced composites, providing precise cutting, drilling, and milling for complex plate applications.

- Decorative & Signage Industry – Excellent for engraving and milling acrylic, PVC, MDF, artificial stone, organic glass, and plastics, as well as soft metals like copper and aluminum, supporting the production of signage, advertising displays, decorative panels, and custom artistic components.

- Custom & Prototyping Applications – Used for 3D modeling, sculpting, artistic carvings, industrial prototypes, and bespoke designs, providing a flexible solution for design studios, manufacturers, and creative workshops.

- Composite Material Machining – Can efficiently process fiberglass, carbon fiber, foam composites, and lightweight non-metal materials, offering high precision for aerospace, automotive, and industrial applications.