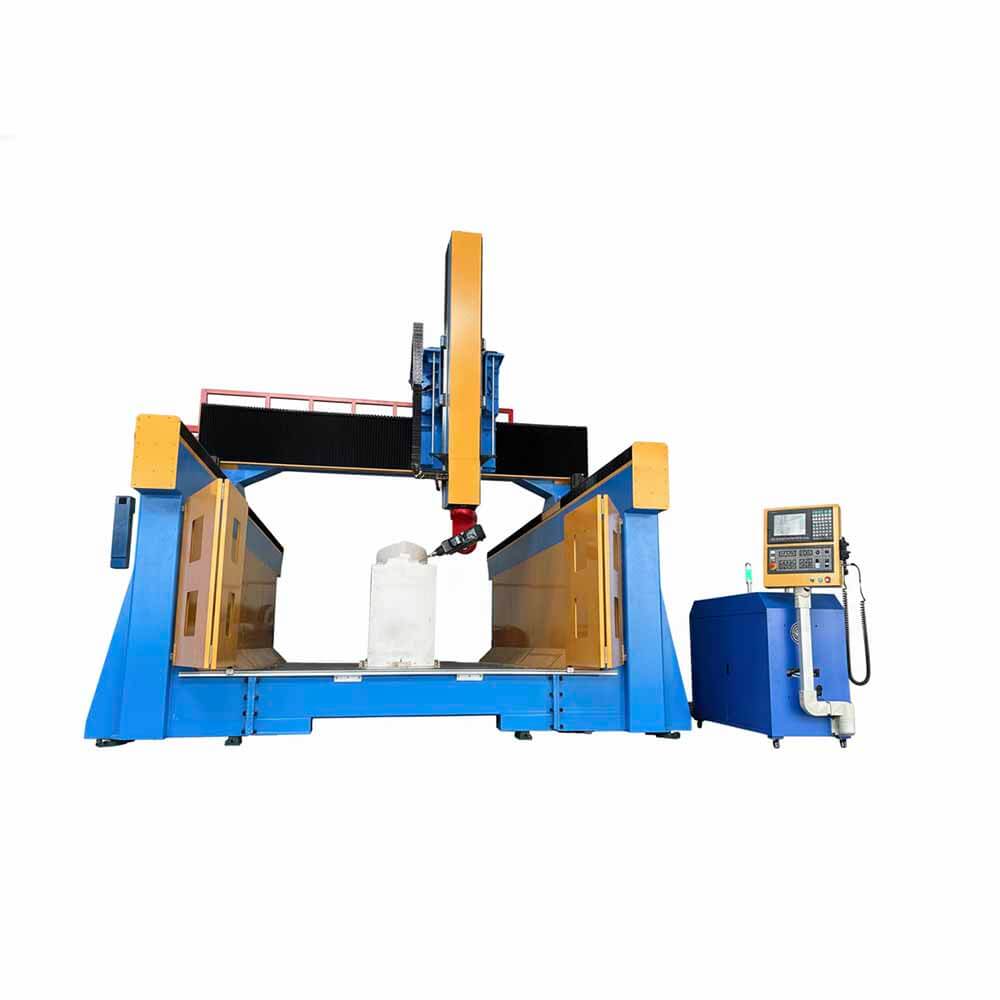

5 Axis CNC Router for Mold Furniture and Decoration

- Model: AC-1330-5 Axis-TABLE

- Working Size: 1300*3000*800MM

- Price Range: $35000.00 to $99500.00 / Set based on the configuration

- Spindle: 10KW HITECO

- Table: Vacuum Table with Gantry Move

- Payment Terms: T/T(Telegraphic Transfer), Visa, Mastercard, American Express, and Discover cards

- Warranty: 2 Years

- Supply Ability: 30 Sets / Month

Description of 5 Axis CNC Router for Mold Furniture and Decoration

The 5 Axis CNC Router for Mold, Furniture, and Decoration is a high-precision machining center designed for creating intricate surfaces and complex 3D shapes with exceptional accuracy. Equipped with full 5-axis simultaneous motion, it enables the spindle to approach the workpiece from multiple angles, making it ideal for producing detailed molds, custom furniture components, decorative panels, and artistic designs.

Built with a rigid, heavy-duty frame, high-accuracy linear guideways, and premium servo drives, this router ensures stable, vibration-free operation even during heavy or large-format work. It is suitable for machining wood, MDF, acrylic, plastics, composite boards, and other non-metallic materials, delivering consistent precision and smooth surface finishes. Perfect for the furniture, interior decoration, and mold-making industries, this 5 Axis CNC Router combines versatility, efficiency, and high-quality results for both custom and production-scale projects.

Features of 5 Axis CNC Router for Mold Furniture and Decoration

- Full 5-Axis XYZAC Movement

The machine features XYZ linear movement combined with A-axis ±110° and C-axis ±245° rotation, enabling milling, trimming, carving, engraving, and contouring of complex surfaces on materials such as fiberglass, carbon fiber, EPS foam, Styrofoam, plastics, aluminum, hardwood, and other composites. Ideal for aerospace components like rocket engine nozzles, space shuttle nose cones, aircraft brake discs, automotive molds, boat and yacht molds, cast dies, and non-metal mold production. - Premium Global Components

All critical components are sourced from world-renowned brands, including Italy DEMAS 5-axis head, HITECO spindle, TPA, OSAI or Syntec CNC controllers, and Japan Yaskawa servo motors and drivers, paired with Helical 3M gears to guarantee high precision up to 0.1 mm, long service life, and minimal maintenance costs. - Heavy-Duty Steel Construction

The machine is built with thick welded steel components (12–20 mm), with gantry legs undergoing high-temperature heat treatment to relieve stress and maximize rigidity. Each leg is precisely milled on a 5-axis CNC center over multiple days to ensure perfect squareness and high torque, maintaining stability and long-term durability. - Precision Working Table

Equipped with a cast iron worktable ranging from 5 to 20 tons depending on material requirements, providing superior rigidity and accuracy for heavy or oversized workpieces. - Laser-Calibrated Alignment

During installation, the machine is calibrated with laser measurement tools to precisely align XYZ and rotary axes, ensuring optimal accuracy and repeatable performance for all 5-axis operations.

Specification of 5 Axis CNC Router for Mold Furniture and Decoration

| No. | Item | Specification |

|---|---|---|

| 1 | X/Y/Z Working Range | 2000 × 3000 × 1000 mm |

| 2 | Table Dimensions | 3700 × 2700 mm |

| 3 | X/Y/Z Positioning Accuracy | ±0.01 mm / 1000 mm |

| 4 | A-Axis Rotation | ±110° |

| 5 | C-Axis Rotation | ±245° |

| 6 | Table Type | Movable worktable |

| 7 | Machine Frame | Heavy-duty steel tube structure with heat treatment |

| 8 | X/Y Axis Transmission | Rack and pinion drive with Hiwin linear guide rails |

| 9 | Z Axis Transmission | Hiwin linear guide rails with TBI precision ball screw |

| 10 | Max Power Consumption (Excluding Spindle) | 12 kW |

| 11 | Maximum Rapid Travel | 40,000 mm/min |

| 12 | Maximum Cutting Speed | 30,000 mm/min |

| 13 | Spindle Power | 12 kW |

| 14 | Spindle Speed | 0–24,000 RPM |

| 15 | Drive Motors | 5000 W Yaskawa servo motors |

| 16 | Operating Voltage | AC 380V, 3-phase, 50/60 Hz (Optional 220V) |

| 17 | Control Language | G-Code |

| 18 | CNC System | Syntec / TPA / OSAI |

| 19 | Computer Interface | USB port |

| 20 | Memory Storage | 512 MB flash |

| 21 | Collet Type | HSK-F63 |

| 22 | X/Y Axis Resolution | <0.01 mm |

| 23 | Software Compatibility | PowerMill, UG software |

| 24 | Operating Temperature | 0–45 °C |

| 25 | Relative Humidity | 30–75% |

| 26 | Packing Dimensions | 5500 × 2100 × 2300 mm |

| 27 | Net Weight | 6000 kg |

| 28 | Gross Weight | 8000 kg |

| 29 | Optional Accessories | Dust collector / dust hood for three axes, vacuum pump, rotary table, mist-cooling system, Delta or Panasonic servo motors, Colombo spindle, Schmalz PTP table |

Application of 5 Axis CNC Router for Mold Furniture and Decoration

The 5 Axis CNC Router is ideal for industries requiring high-precision machining of complex shapes and detailed surfaces. In the mold-making industry, it is used to produce large-scale molds for automotive parts, aerospace components, boat hulls, and casting dies, ensuring high accuracy and surface quality. In furniture manufacturing, it efficiently creates intricate designs, 3D carvings, decorative panels, wooden doors, cabinet fronts, and customized woodwork, supporting both mass production and custom projects.

For decorative and interior design, this machine excels in producing ornate moldings, artistic reliefs, 3D sculptures, signage, and architectural elements from wood, MDF, acrylic, plastics, and composite materials. Its ability to handle multi-dimensional surfaces and curved geometries makes it a versatile solution for high-end furniture, interior decoration, mold prototypes, and artistic craftsmanship, delivering consistent precision, repeatability, and efficiency.