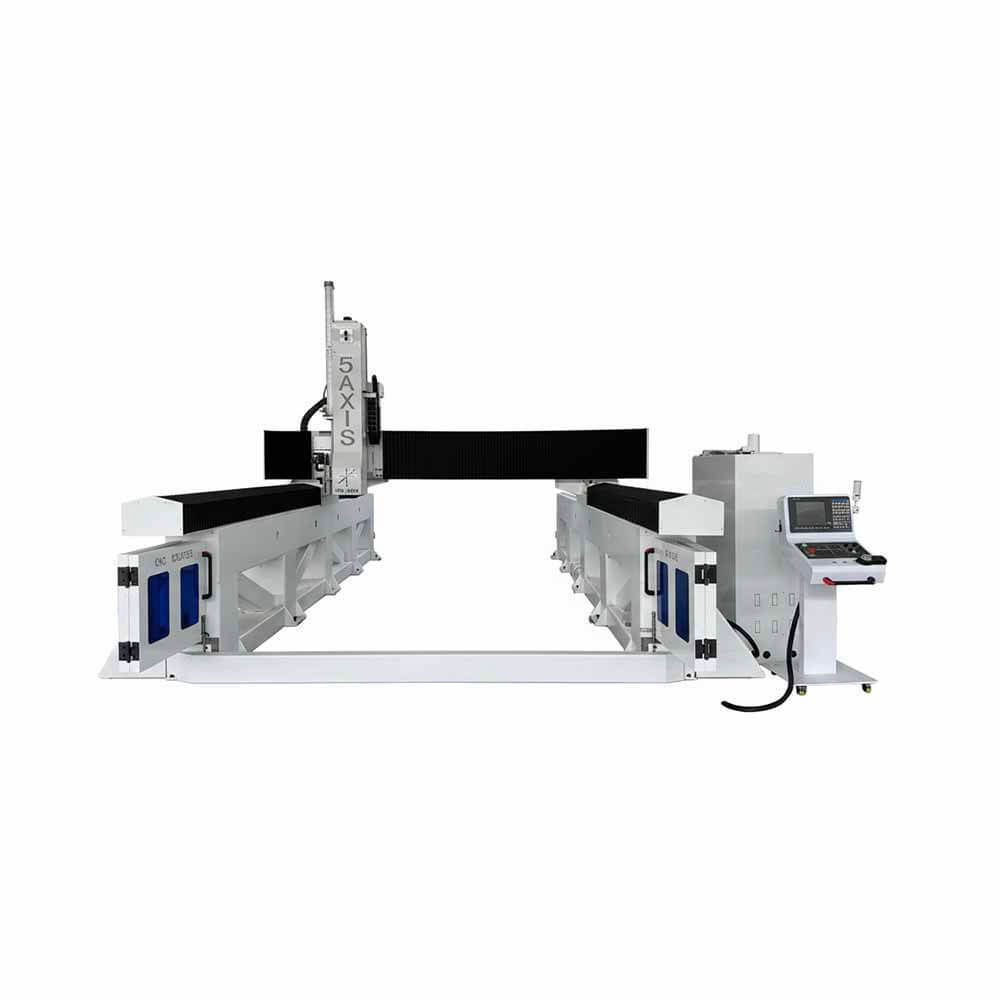

5 Axis CNC Router High Accuracy and Stable Performance

- Model: AC-2040-5 Axis-TABLE

- Working Size: 2000*4000*1000MM

- Price Range: $55000.00 to $99500.00 / Set based on the configuration

- Spindle: 10KW HITECO

- Table: Vacuum Table with Gantry Move

- Payment Terms: T/T(Telegraphic Transfer), Visa, Mastercard, American Express, and Discover cards

- Warranty: 2 Years

- Supply Ability: 30 Sets / Month

Description of 5 Axis CNC Router High Accuracy and Stable Performance

The 5 Axis CNC Router with High Accuracy and Stable Performance is engineered for advanced machining applications that demand precision, speed, and reliability. With simultaneous five-axis interpolation, a rigid heavy-duty frame, and premium transmission components, this CNC router delivers exceptional accuracy even during long-duration, high-speed machining. Its multi-axis capability allows the spindle to approach the workpiece from any angle, enabling the efficient production of complex 3D surfaces, deep cavities, curved panels, molds, prototypes, and intricate contours. Equipped with high-precision servo motors, reinforced structural design, intelligent control systems, and vibration-free operation, the machine maintains consistent performance for wood, aluminum, foam, composite materials, plastics, and other non-metal applications. Designed for continuous industrial use, it ensures superb machining quality, excellent repeatability, and long-term stability, making it ideal for aerospace manufacturing, automotive prototyping, mold making, artistic carving, and high-end woodworking production.

Features of 5 Axis CNC Router High Accuracy and Stable Performance

- Equipped with imported four-row linear bearings and heavy-duty guide rails, paired with self-lubricating sliders to ensure smooth motion, consistent force, and long-term mechanical accuracy and stability.

- The Z-axis offers an extended travel of up to 1 meter, making it ideal for machining larger, thicker, and oversized materials with ease.

- Built-in smart overtravel protection system prevents accidental crashes caused by exceeding the machining area, enhancing operational safety.

- Advanced multifunction control panel allows precise adjustment of cutting speed, feed rate, and travel speed, greatly boosting machining quality and overall productivity.

- Reinforced structural design ensures strong rigidity, reduces vibration during high-speed processing, and maintains excellent precision for demanding applications.

- High-efficiency motion control system delivers smoother interpolation, faster response, and improved performance across complex 3D machining tasks.

- User-friendly interface supports seamless programming and real-time monitoring, reducing operator training time and enhancing workflow efficiency.

Specification of 5 Axis CNC Router High Accuracy and Stable Performance

| No. | Item | Specification |

|---|---|---|

| 1 | Model | AC-2040 |

| 2 | Working Envelope (X/Y/Z) | 2000 × 4000 × 1000 mm |

| 3 | Tool Changer | Linear automatic tool changer with 8-tool capacity |

| 4 | Worktable Surface | Vacuum + T-slot hybrid table, divided into 6 working zones |

| 5 | Machine Frame | Heavy-duty industrial square tube construction (8–10 mm steel) |

| 6 | X/Y Transmission | Precision rack-and-pinion system with Taiwan HIWIN #25 linear guideways |

| 7 | Z Transmission | Taiwan HIWIN #25 linear guides paired with TBI ball screw |

| 8 | Spindle Unit | 9 kW Italian HSD ATC air-cooled spindle, ±90° swing rotation |

| 9 | Spindle Speed Range | 0–24,000 RPM |

| 10 | Servo System | 850W Yaskawa servo motors and matching drivers |

| 11 | Inverter | 11 kW DELTA inverter from Taiwan |

| 12 | Power Supply | 380V, 3-phase, 60Hz (Optional: 220V, 3-phase, 50/60Hz) |

| 13 | Programming Language | Standard G-Code |

| 14 | CNC Controller | Taiwan SYNTEC 4-axis control system with handheld unit |

| 15 | Data Interface | USB connectivity |

| 16 | Reducer | Japan Shimpo precision reducer |

| 17 | Vacuum System | 4 kW Becker vacuum pump (Germany) |

| 18 | Compatible Software | POWERMILL (optional upgrade) |

| 19 | Lubrication | Fully automatic lubrication system |

| 20 | Tool Calibration | Automatic tool length sensor |

| 21 | Operating Conditions | Temperature range: 0–45°C |

| 22 | Shipping Dimensions | 4500 × 2300 × 3200 mm |

| 23 | Net Weight | 3000 kg |

| 24 | Gross Weight | 3500 kg |

Application of 5 Axis CNC Router High Accuracy and Stable Performance

- Automotive & Industrial Mold Manufacturing:

Ideal for machining foam patterns for automotive stamping molds, producing wooden casting molds, shaping automotive interior components, and processing engineering plastics. Perfect for carving, trimming, and contouring a wide range of non-metallic materials such as EPS foam, PU foam, resin blocks, composite materials, and prototype parts. - Furniture & Woodworking Industry:

Widely used for creating wooden doors, cabinet panels, custom furniture, office furniture, tables, chairs, window frames, decorative panels, relief carvings, and other precision wood products. Supports detailed engraving, 3D carving, profiling, and shaping across solid wood, MDF, plywood, and composite boards. - Wood Mold & Pattern Making:

Suitable for manufacturing casting patterns, automotive inspection fixtures, prototype molds, sculpted wood models, complex 3D shapes, and other non-metal mold applications. The machine offers excellent performance for machining wood molds, architectural models, tooling boards, and engineering plastics with smooth, high-precision results.