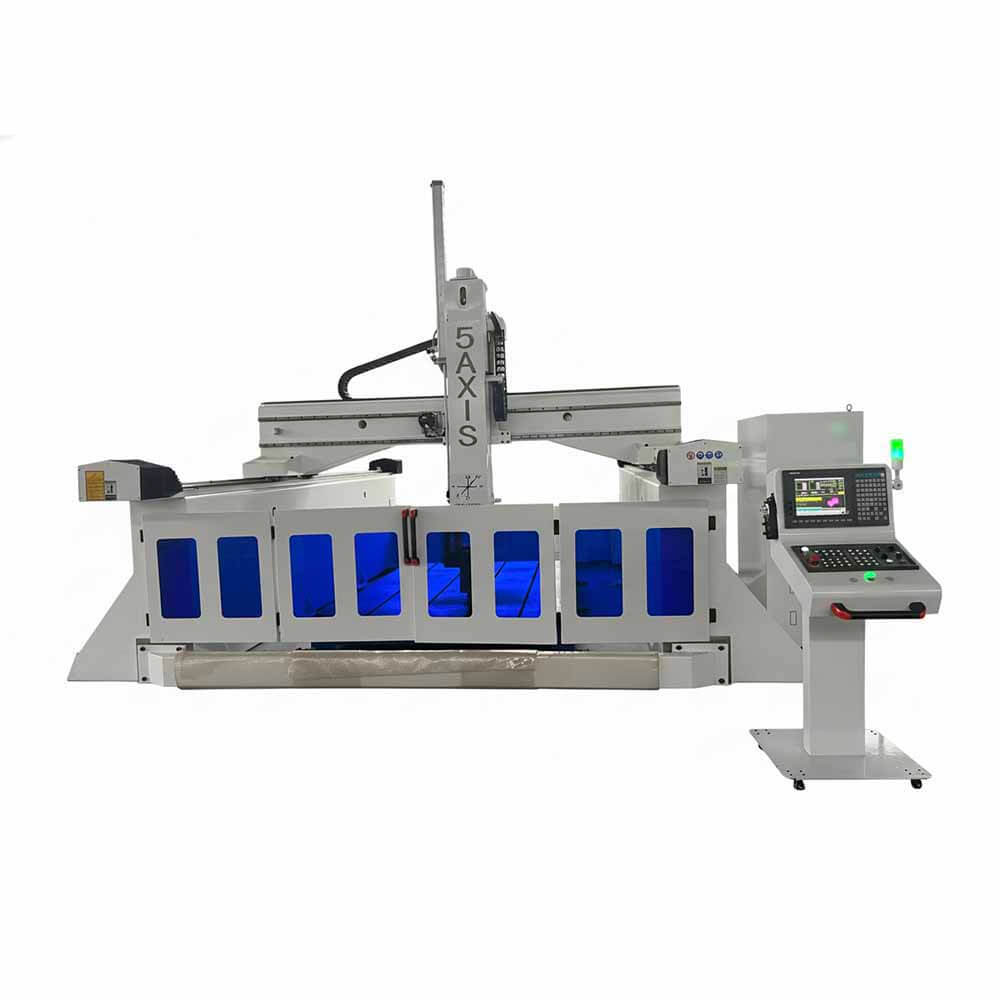

5 Axis CNC Router Machine for Aerospace Components

- Model: AC-2030-5 Axis-TABLE

- Working Size: 2000*3000*1000MM

- Price Range: $55000.00 to $99500.00 / Set based on the configuration

- Spindle: 10KW HITECO

- Table: Vacuum Table with Gantry Move

- Payment Terms: T/T(Telegraphic Transfer), Visa, Mastercard, American Express, and Discover cards

- Warranty: 2 Years

- Supply Ability: 30 Sets / Month

Description of 5 Axis CNC Router Machine for Aerospace Components

The 5 Axis CNC Router Machine for Aerospace Components is a high-precision machining solution engineered for the complex demands of the aerospace industry. With full five-axis simultaneous movement, the spindle can approach the workpiece from any angle, enabling intricate 3D surface machining, deep cavities, and multi-sided component processing with exceptional accuracy.

Built on a heavy-duty, heat-treated steel structure with reinforced ribs, the machine ensures superior rigidity, vibration-free operation, and long-term stability, even during high-speed milling of aluminum, composites, and lightweight aerospace materials. Equipped with advanced RTCP functionality and five-axis interpolation, it delivers precise tool path control for complex geometries, ensuring dimensional accuracy and consistency across critical aerospace parts.

The router is compatible with premium CNC systems such as Taiwan Syntec, OSAI, or TPA, offering user-friendly operation, smooth motion control, and reliable performance. Ideal for producing molds, structural components, prototype models, and complex contoured parts, this 5-axis CNC router provides aerospace manufacturers with the precision, efficiency, and flexibility required for high-value, mission-critical components.

Features of 5 Axis CNC Router Machine for Aerospace Components

- Spacious Working Envelope – Large-format machining area of 2000 × 3000 × 1000 mm, with Z-axis travel expandable to 1.5 meters, ideal for large-scale 3D surface processing and sculpting.

- Advanced 5-Axis Spindle Head – Equipped with a DEMAS 5-axis head and Hiteco water-cooled spindle, HSK F63, ensuring high-speed precision cutting and stability.

- High-Performance Servo System – Taiwan SYNTEC 1.5 kW servo drives deliver smooth, accurate axis movement for reliable multi-axis machining.

- User-Friendly CNC Control – Taiwan SYNTEC control system supports full 5-axis simultaneous motion and automatic tool changer (ATC) functionality for complex operations.

- Precision Motion Components – Helical rack and pinion drive for X and Y axes, combined with Taiwan TBI high-precision ball screw for Z-axis travel, ensures smooth and accurate positioning.

- Robust Linear Guide System – Dual HIWIN #35 linear rails on each side of the Y-axis (total 4 rails) for maximum stability and precise movement.

- X & Z Axis Stability – Taiwan HIWIN #35 linear guides provide consistent, high-accuracy motion for X and Z axes.

- High-Precision Ball Screws – Taiwan TBI ball screws deliver excellent positioning repeatability and long-term durability.

- Dust Protection System – Axis dust covers, dust collection hoods, and piping ensure a clean working environment and reduce machine wear.

- Heavy-Duty Structure – Reinforced gantry and machine frame made from 12 mm thick steel provide maximum rigidity, vibration resistance, and long-term stability during high-speed 5-axis machining.

Specification of 5 Axis CNC Router Machine for Aerospace Components

| Item | Specification |

|---|---|

| Working Area (X/Y/Z) | 2000 × 3000 × 1000 mm (customizable Z-axis up to 1.5 m) |

| Packing Dimensions | 5000 × 2500 × 2560 mm |

| CNC Control System | Syntec 5-axis controller with ATC support |

| Spindle Head | DEMAS 5-axis head with Hiteco water-cooled spindle, HSK F63 |

| Spindle Speed | 6,000 – 24,000 RPM |

| Inverter | Taiwan DELTA inverter |

| Drive Motors | SYNTEC high-performance servo motors |

| Power Supply | AC 380V, 50–60 Hz, single-phase |

| Transmission System | Taiwan TBI precision ball screws |

| Linear Guide Rails | Taiwan HIWIN Ø35 mm square linear guides |

| Machining Accuracy | ±0.02 mm |

| Table Surface | Double-layer PVC |

| Programming Language | Standard G-code |

Application of 5 Axis CNC Router Machine for Aerospace Components

- Wood & Furniture Manufacturing: Perfect for producing wave panels, intricate patterns, antique-style furniture, wooden doors, decorative screens, craft sashes, composite gates, cupboard doors, interior doors, sofa legs, headboards, and other detailed wood components.

- Signage & Advertising Industry: Ideal for creating advertising signage, acrylic engraving and cutting, crystal letters, promotional displays, mold-making for signage, and other custom advertising materials and decorative elements.

- Automotive & Mold Making: Suitable for automotive mold production, EPS foam models, wooden casting molds, car interior decorative parts, engineering plastics, and a variety of other non-metallic materials used in prototyping and industrial applications.