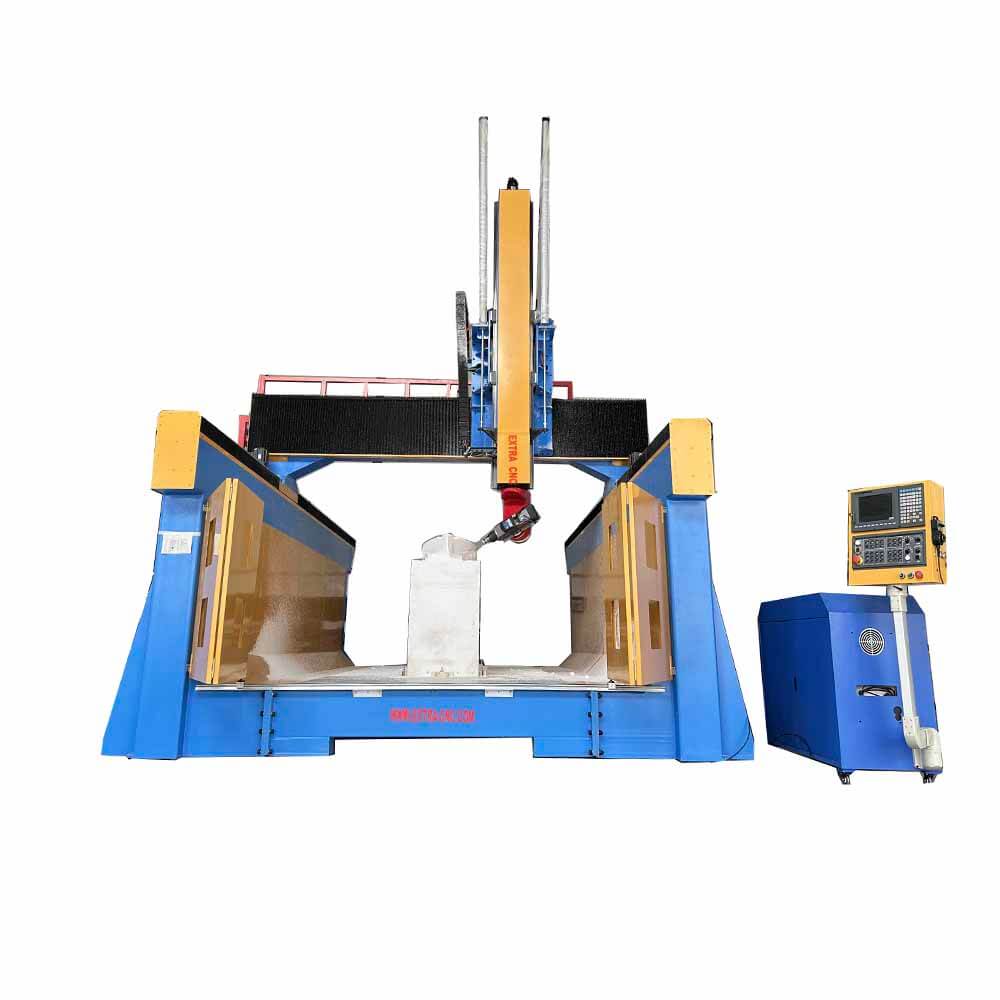

Efficient Foam Cutting with 5 Axis CNC Routers

- Working Size: Double Table 2*1200*1200*800mm

- Price Range: $39000.00 to $99500.00 / Set based on the configuration

- Supply Ability: 30 Sets / Month

- Warranty : 12 month Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- Payment Terms : Online (T/T, PayPal, Trade Assurance) / Offline (T/T, LC, Credit Cards)

(4.9 based on 107 ratings and reviews)

5 Axis CNC routers cut foam with speed and precision, easily handling complex 3D shapes and deep angles—perfect for props, molds, and sculptures.

Description of Efficient Foam Cutting with 5 Axis CNC Routers

5 Axis CNC routers deliver exceptional efficiency in foam cutting by enabling complex, multi-angle machining in a single setup. Their advanced motion control allows precise 3D shaping, deep undercuts, and smooth surface finishes—ideal for producing large-scale sculptures, props, molds, and prototypes. With automatic tool changes, high-speed spindles, and intelligent control systems, these machines reduce production time, minimize material waste, and ensure consistent, high-quality results across all foam fabrication tasks.

Features of Efficient Foam Cutting with 5 Axis CNC Routers

- Robust and Rigid Machine Structure

The machine features a reinforced frame that ensures superior strength, excellent precision, and long-term reliability for heavy-duty and high-accuracy CNC operations. - Imported Precision Ball Screw Transmission

Equipped with a top-grade imported ball screw, the machine delivers ultra-smooth motion and high positioning accuracy, crucial for detailed cutting and engraving tasks. - HIWIN/PMI Linear Guides with Extended Lifespan

Utilizing high-quality linear guide rails from HIWIN or PMI, the system offers exceptional durability—lasting up to 10 times longer than traditional round guides—and provides stable, distortion-resistant motion. - Dual Working Tables for High Efficiency

The double moving table design allows simultaneous setup and machining, significantly improving productivity and reducing downtime. - High-Speed Servo Motors for Accurate Performance

Driven by high-torque, responsive servo motors, the CNC machine ensures fast operation speeds while maintaining precision, making it ideal for both intricate and large-scale projects. - Advanced Syntec CNC Control System

Featuring the user-friendly and reliable Syntec control system, the machine supports stable performance and broad compatibility with various processing applications. - Smart Breakpoint Resume Function

The system includes advanced memory capabilities such as breakpoint recovery, automatic resume after power failure, and accurate job time estimation, helping avoid losses from unexpected interruptions. - Automatic Lubrication System

Integrated automatic oiling ensures consistent lubrication of key components, extending machine life and reducing maintenance efforts. - Dust-Proof and Water-Proof Design

Designed for harsh workshop environments, the machine’s protective housing and sealing mechanisms safeguard internal components from dust, moisture, and debris.

Application of Efficient Foam Cutting with 5 Axis CNC Routers

Woodworking & Furniture Manufacturing

Ideal for crafting solid wood furniture components such as cabinet doors, dining tables, chairs, wave panels, intricate decorative patterns, classical and antique-style furniture, wooden doors, partitions, decorative screens, carved panels, composite entryways, wardrobe doors, interior room doors, sofa legs, bed headboards, and much more.

Advertising & Signage Industry

Perfect for producing various advertising elements including 3D logos, signs, nameplates, exhibition displays, conference panels, promotional boards, signage fabrication, acrylic cutting and engraving, crystal lettering, wooden display crafts, blister forming molds, and customized promotional material components.

Mold & Model Industry

Well-suited for processing large non-metal molds, especially automotive foam molds, marine wood models, aviation prototypes, rail transit wooden molds, and train body mockups.

Instrument Manufacturing

Used for complex 3D contour carving and profile cutting of large-sized instrument enclosures and precision wooden housing components.

Parameters of Efficient Foam Cutting with 5 Axis CNC Routers

Parameters of Efficient Foam Cutting with 5 Axis CNC Routers

| Item | Specification |

|---|---|

| Model Number | ET-1224-5AXIS |

| Machine Frame | Heavy-duty thick-walled steel tube welded structure |

| Working Area (Single Table) | X: 1200mm Y: 1200mm Z: 600mm |

| Table Size (Single) | 1200mm × 1200mm |

| Worktable Type | Aluminum T-slot worktable with tooling fixture support |

| Drive System – X Axis | 30mm HIWIN square linear guide rail + TBI ball screw (Taiwan) |

| Drive System – Y Axis | 30mm HIWIN square linear guide rail + TBI ball screw (Taiwan) |

| Drive System – Z Axis | 30mm HIWIN square linear guide rail + TBI ball screw (Taiwan) |

| Spindle Motor | 7.5kW Air-Cooled Automatic Tool Changer (ATC) Spindle |

| Spindle Speed | Max 18,000 RPM |

| Cooling System | Air cooling with optional water pump support |

| Collet Size | ER32 Ø3.175, 4, 6, 8, 12.7mm |

| Inverter Model | DZB200M2005.5L – Fuling |

| Motor & Driver – X Axis | Syntec 1000W servo motor with matching driver |

| Motor & Driver – Y Axis | Syntec 1000W servo motor with matching driver |

| Motor & Driver – Z Axis | Syntec 1000W servo motor with driver and safety brake |

| Control System | Syntec CNC Controller with RCTP (Real-Time Continuous Path) |

| Data Processing Mode | Line-by-line G-code interpretation |

| Supported File Formats | G-code / PLT / DXF / ENG |

| A-Axis Swing Range | -120° to +120° |

| C-Axis Rotation Range | -400° to +400° |

| Operating Voltage | 3 Phase, AC 380V, 50/60Hz |

| Positioning Accuracy | ±0.05mm |

| Rotational Speed | A-Axis: 170°/sec C-Axis: 270°/sec |

| Feed Rate – XY Axis | 0 – 30,000 mm/min |

| Feed Rate – Z Axis | 0 – 25,000 mm/min |

| Acceleration – XYZ | Up to 3m/s² |

| Gantry Construction | Reinforced thick steel tubing |

| Lubrication System | Fully automatic oiling system |

| Power Failure Memory | Resume carving from breakpoints and outages |

| Tool Kit | Tool box provided |

| After-Sales Service | Online technical support available |

| Warranty Period | 36 Months (3 Years) |

| Technical Support | Remote assistance via phone or online |

| Spare Parts Support | Full support for damaged or consumable components |

| Machine Weight | 4,500 kg |

| Lead Time | Ready to ship within 5 working days |

| Overall Dimensions (L×W×H) | 4.2m × 3.2m × 3.7m |