5 Axis CNC Router for Aluminum Wood and Foam

- Model: AC-1525-5 Axis-TABLE

- Working Size: 1500*2500*1000MM

- Price Range: $55000.00 to $99500.00 / Set based on the configuration

- Spindle: 10KW HITECO

- Table: Vacuum Table with Gantry Move

- Payment Terms: T/T(Telegraphic Transfer), Visa, Mastercard, American Express, and Discover cards

- Warranty: 2 Years

- Supply Ability: 30 Sets / Month

Description of 5 Axis CNC Router for Aluminum Wood and Foam

The 5 Axis CNC Router for Aluminum, Wood, and Foam is a high-precision machining center designed for complex 3D cutting, carving, and engraving across a variety of materials. Featuring full 5-axis motion, the spindle can approach the workpiece from any angle, enabling intricate designs, deep undercuts, and multi-surface machining with exceptional accuracy. Built on a heavy-duty, heat-treated steel frame with reinforced ribs, the machine provides outstanding stability and vibration-free operation. Ideal for aluminum, hardwood, composite boards, and foam, it is perfect for mold making, furniture components, 3D prototypes, signage, and artistic designs. Equipped with premium spindles, precision linear guides, servo motors, and advanced control systems, along with optional vacuum tables, automatic tool changers, and dust collection, this router delivers reliable performance, efficiency, and flexibility for professional manufacturing environments.

Features of 5 Axis CNC Router for Aluminum Wood and Foam

- Heavy-Duty Industrial Frame – Reinforced structure with high-temperature tempering ensures maximum rigidity and long-lasting stability.

- High-Precision 5-Axis Machining – Accurately milled and drilled guide rails and racks deliver superior movement accuracy for complex 3D operations.

- Advanced Accuracy Verification – Precision tested with dial indicators and Renishaw laser interferometers for ultra-precise calibration.

- Professional Finish – Smooth, high-quality paint protects the machine while giving a polished, professional appearance.

- Safe & Reliable Packaging – Sturdy packaging guarantees secure transportation and delivery without damage.

Specification of 5 Axis CNC Router for Aluminum Wood and Foam

| No. | Item | Specification |

|---|---|---|

| 1 | Model Name | AC-1525 5-Axis CNC Router |

| 2 | Machine Type | Table-move / Gantry style |

| 3 | Working Area (X×Y×Z) | 1500 × 2500 × 800 mm |

| 4 | Rotary Axes Travel | C-axis: ±220° |

| 5 | Dual Pendulum Head | HS400 |

| 6 | Pendulum Head Supplier | HSD |

| 7 | Spindle Power | 10 kW |

| 8 | Spindle Speed | 0–24,000 RPM |

| 9 | Table Size | 1500 × 2500 mm |

| 10 | Table Material | Cast steel / T-slot clamping |

| 11 | Machine Frame | Heavy-duty welded steel with heat treatment |

| 12 | Axis Drive | X/Y: Rack & Pinion with linear guides |

| 13 | Max Axis Speed | X/Y: 40 m/min |

| 14 | Positioning Accuracy | ±0.01 mm per 1000 mm |

| 15 | Repeatability | ±0.01 mm |

| 16 | Control System | Syntec / OSAI / TPA |

| 17 | Programming Language | G-code |

| 18 | Connectivity | USB / CF card / Cable transmission |

| 19 | Voltage | AC 380V 3-Phase 50Hz (220V optional) |

| 20 | Operator Training | Minimum 2 weeks |

| 21 | Machine Dimensions | 3000 × 4000 × 2500 mm |

| 22 | Total Weight | 12,000 kg |

| 23 | Optional Accessories | Automatic tool changer, vacuum table, dust collection, mist cooling, rotary attachments |

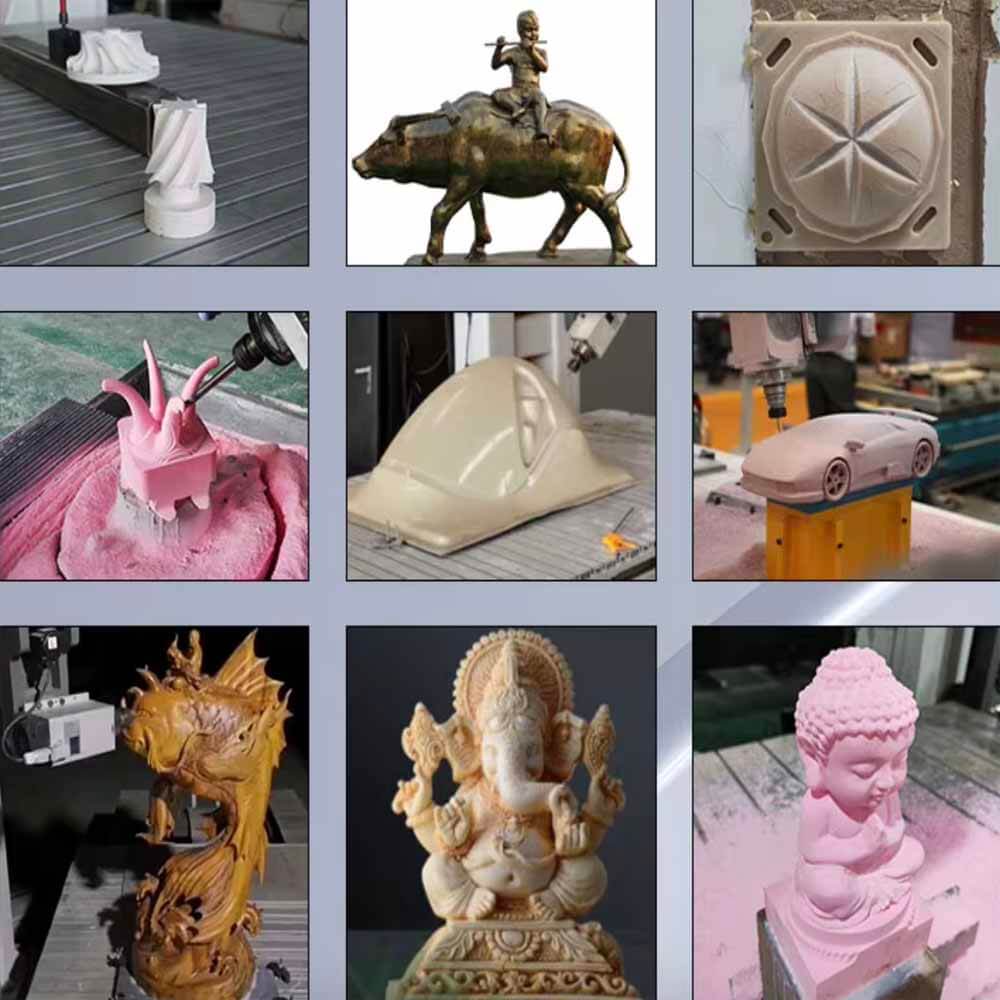

Application of 5 Axis CNC Router for Aluminum Wood and Foam

The 5 Axis CNC Router for Aluminum, Wood, and Foam is ideal for industries and applications that require high-precision, multi-surface machining. In the mold and die industry, it is perfect for carving and shaping non-metallic materials such as foam, PVC, plastics, and wood blocks to create detailed molds and sculptures. In automotive, aerospace, and marine industries, it can produce complex molds, prototypes, and formwork for car bodies, boat hulls, aviation parts, and other industrial patterns. For the sheet and composite material sector, the router efficiently handles insulation boards, plastic and chemical sheets, PCBs, composite panels, epoxy, resin, ABS, PP, PE, and other carbon-fiber or mixed-material sheets. Its ability to handle intricate 3D surfaces and precise multi-axis movements makes it indispensable for furniture manufacturing, signage, prototype modeling, decorative elements, and other applications where accuracy, speed, and surface quality are critical.