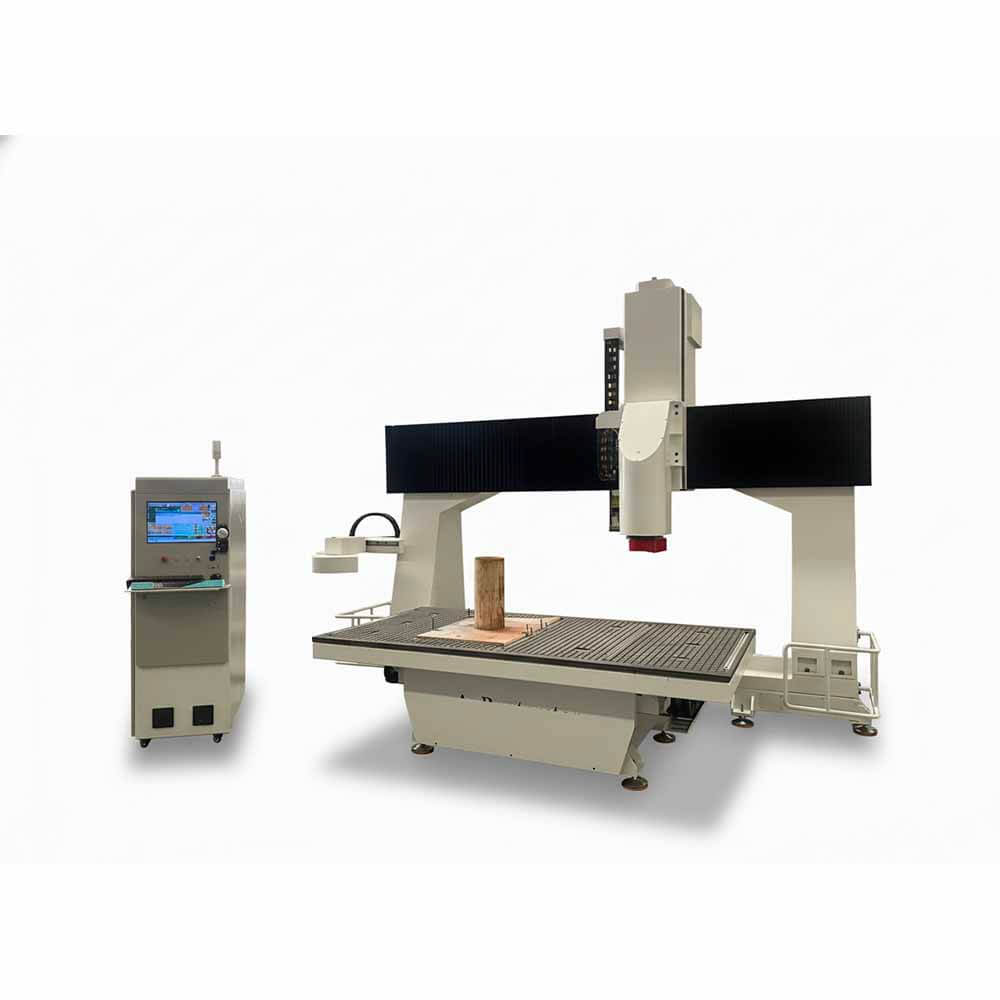

Comparing 3+2 Axis vs True 5 Axis CNC Routers: What You Need to Know for Complex Machining

When evaluating CNC router options for complex components, engineers and manufacturers often encounter two terms: 3+2 axis and true 5 axis. While both involve five axes of movement, their operational capabilities, machining strategies, and applications differ significantly.