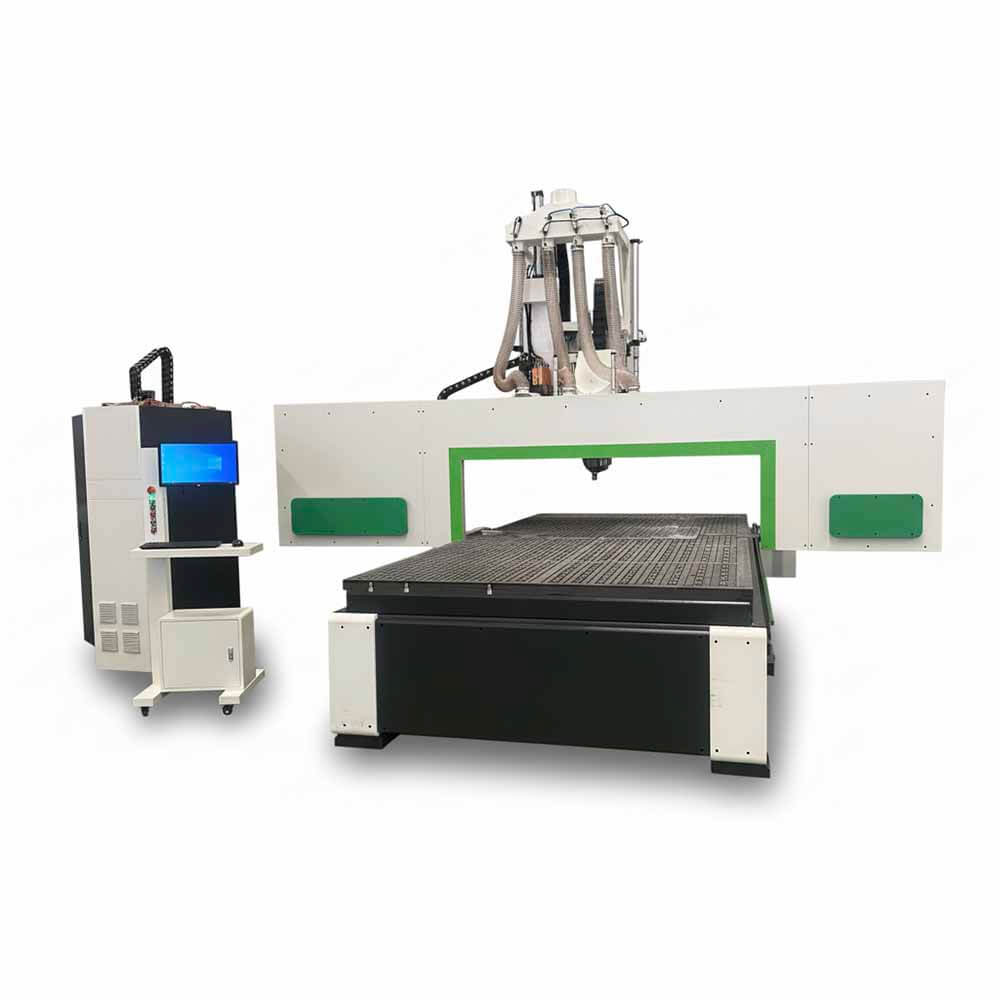

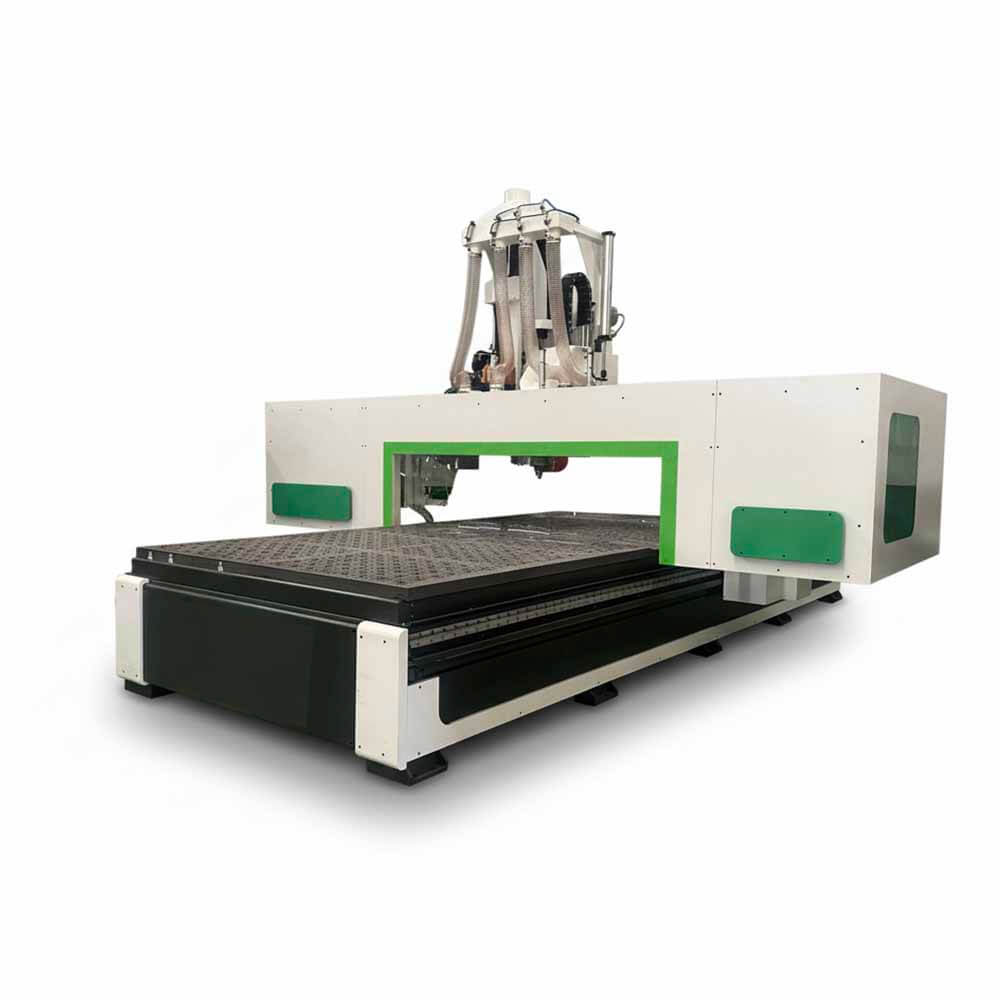

Is a 5 Axis CNC Router Worth It for Woodworking and Furniture Manufacturing?

For woodworking shops and furniture manufacturers, productivity, accuracy, and flexibility are critical. As product designs become more complex and customer expectations increase, many businesses start asking an important question: