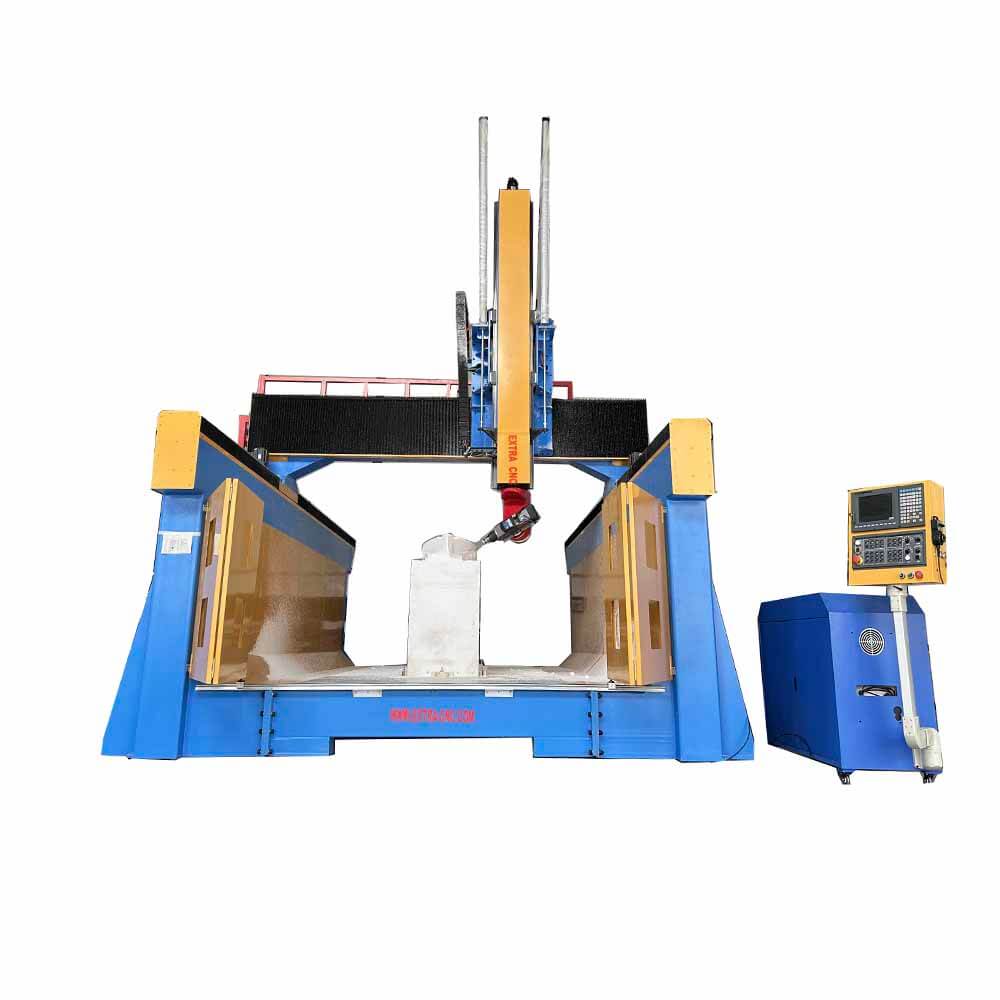

5-Axis CNC Router for Precision and Complex 3D Mold Making

- Working Size: 2000*3000*1000mm

- Price Range: $49000.00 to $99500.00 / Set based on the configuration

- Supply Ability: 30 Sets / Month

- Warranty : 12 month Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- Payment Terms : Online (T/T, PayPal, Trade Assurance) / Offline (T/T, LC, Credit Cards)

(4.9 based on 107 ratings and reviews)

High-precision 5-Axis CNC Router designed for complex 3D mold making. Ideal for automotive, aerospace, and industrial mold manufacturing with exceptional accuracy and surface finish.

Description of 5-Axis CNC Router for Precision and Complex 3D Mold Making

The 5-Axis CNC Router is engineered for high-precision and intricate 3D mold manufacturing. Equipped with advanced multi-axis control, it delivers exceptional accuracy and surface finish for complex mold shapes used in automotive, aerospace, and industrial applications. This router efficiently handles a variety of materials including metals, composites, and plastics, enabling detailed contouring, carving, and milling. Its robust construction and reliable components ensure consistent performance, making it ideal for producing sophisticated molds with tight tolerances and complex geometries.

Features of 5-Axis CNC Router for Precision and Complex 3D Mold Making

- The Model 5-axis CNC router is equipped with a premium imported DEMAS 5-axis head, designed specifically for advanced 4D and 5D machining. The C-axis offers a rotation range of ±245 degrees, while the A-axis rotates ±120 degrees for versatile multi-axis operations.

- Key components of this 5-axis CNC router are sourced from internationally renowned manufacturers, including the Italian HITECO ATC spindle, Syntec control system, Yaskawa/Syntec servo motors, Shimpo gear reducer, and Fuling/Delta frequency inverters. These world-class parts guarantee stable and high-performance operation.

- This router enables intricate surface engraving, complex curved surface milling, and bent surface machining suited for 4D and 5D processing tasks—perfect for creating uniquely shaped artworks, curved doors, and customized cabinetry.

- The machine is compatible with a variety of materials such as foam, MDF, acrylic, wood, and soft metals, offering flexible application across different industries.

Application of 5-Axis CNC Router for Precision and Complex 3D Mold Making

This machine is suitable for processing a wide range of materials including foam (EPS), wood, soft metals, plastics, acrylic, stone, PVC, and composite panels. It can efficiently perform multi-angle operations such as slotting, chamfering, drilling, and groove milling.

- Mold Manufacturing: Ideal for producing large-scale metal molds, especially automotive foam molds, wooden ship prototypes, aircraft models, railway wooden molds, and train mock-ups.

- Instrumentation: Perfect for 3D surface engraving and contour cutting of large industrial instruments and devices.

- Signage & Material Fabrication: Used for crafting signs and processing plastics, wood, and mold components.

- Furniture & Woodworking: Suitable for general furniture production and various woodworking manufacturing tasks.

Parameters of 5-Axis CNC Router for Precision and Complex 3D Mold Making

| Item | Specification Details |

|---|---|

| Machine Type | 5-Axis CNC Router (Model 2030) |

| Working Area | 2000 mm × 3000 mm |

| Z-Axis Travel | 2000 mm |

| B-Axis Rotation | ±130° |

| C-Axis Rotation | ±200° (adjustable from 0 to 400°) |

| Spindle | DEMAS 5-axis head with HITECO 12 kW spindle, 1000–24,000 RPM |

| Maximum Rapid Speed | Up to 6000 mm/min |

| Feed Rates | X, Y axes: 0–40 mm/min; Z axis: 0–20 mm/min |

| Control System | Syntec CNC system (Taiwan) |

| Servo Motors | YASKAWA servo motors (Japan) |

| Supported Software | Compatible with Cimatron, UG, MasterCAM, PRO-E, CATIA, CAD, etc. |

| Frequency Inverter | Delta brand inverter |

| Transmission Components | TBI ball screws and HIWIN linear guide rails |

| Vacuum System | 60 m³/h, 2.2 kW vacuum pump (included if vacuum table option selected) |

| Power Supply | 380 V, 50 Hz, 3-phase |

| Machine Weight | Approximately 6000 kg |