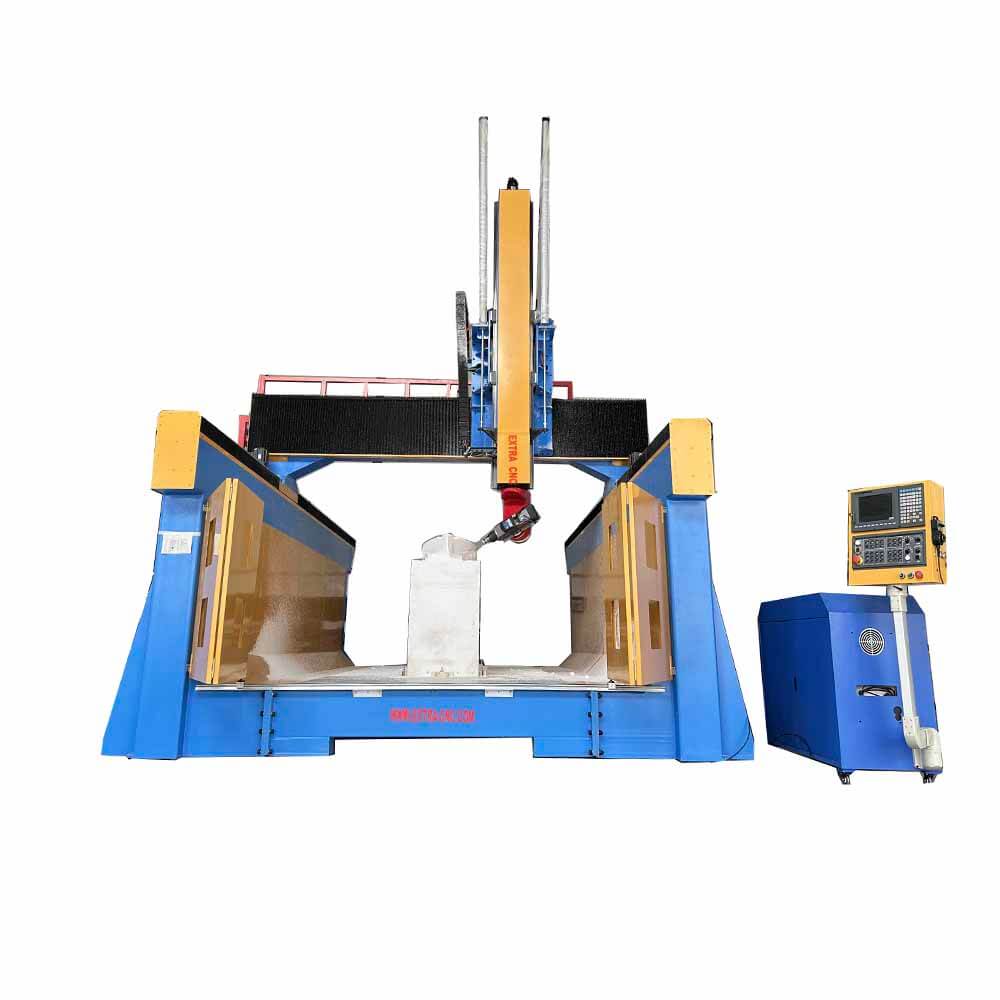

5-Axis CNC Router for 3D Fiber Boat Die Mold Milling & Making

- Working Size: 1300*2500*600mm

- Price Range: $9000.00 to $9500.00 / Set based on the configuration

- Supply Ability: 30 Sets / Month

- Warranty : 12 month Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- Payment Terms : Online (T/T, PayPal, Trade Assurance) / Offline (T/T, LC, Credit Cards)

(4.9 based on 107 ratings and reviews)

High-precision 5-Axis CNC Router designed for 3D milling and manufacturing of fiber boat die molds. Ideal for complex shapes with excellent accuracy and surface finish.

Description of 5-Axis CNC Router for 3D Fiber Boat Die Mold Milling & Making

The 5-Axis CNC Router is specifically designed for precision milling and manufacturing of complex 3D fiber boat die molds. Equipped with advanced multi-axis control and a high-speed spindle, it delivers exceptional accuracy and surface quality for intricate mold geometries. This machine excels at machining fiber composites, foam, and plastic materials commonly used in boat mold fabrication. Its robust build and premium components ensure durability and consistent performance, making it an ideal solution for the marine industry’s demanding mold production needs.

Features of 5-Axis CNC Router for 3D Fiber Boat Die Mold Milling & Making

- High-precision 5-axis machining capability ideal for complex 3D fiber boat die mold milling and fabrication.

- Advanced multi-axis control allows accurate contouring, curved surface milling, and detailed sculpting of fiber composite materials.

- Equipped with a powerful spindle supporting high-speed rotation, ensuring smooth cutting and fine surface finishes on fiber and composite molds.

- Utilizes premium components including imported CNC controllers, servo motors, and precision ball screws for consistent and reliable performance.

- Automatic tool changer (ATC) system reduces tool change time, increasing productivity and minimizing downtime during mold manufacturing.

- Compatible with industry-leading CAD/CAM software for seamless integration and efficient programming of complex mold geometries.

- Robust machine construction designed to handle large mold sizes and heavy-duty milling tasks with excellent rigidity and stability.

- Safety features such as emergency stop, collision detection, and overload protection enhance operator safety and machine longevity.

- Suitable for machining a variety of materials used in boat mold production, including fiber composites, foam, and plastics.

Application of 5-Axis CNC Router for 3D Fiber Boat Die Mold Milling & Making

- Mold manufacturing sector, decorative arts industry, and furniture production field.

- Large-scale metal-like molds, architectural scale models, automotive foam mold fabrication, wooden ship prototypes, railway wooden molds, wooden aircraft models, and wooden train molds.

- Signage and display manufacturing for commercial advertising.

- Instrumentation industry for 3D engraving and precision component shaping.

Parameters of 5-Axis CNC Router for 3D Fiber Boat Die Mold Milling & Making

| Specification | Details |

|---|---|

| Working Dimensions | 1300 × 2500 × 600 mm; C-axis rotation ±360°, A-axis ±110° |

| Machine Frame | Heavy-duty cast steel construction |

| Spindle Motor | Italian HITECO 10 kW 5-axis spindle |

| Tool Changer | Disc-style automatic tool changer with 8 tool slots |

| Spindle Speed Range | 6000 to 24,000 RPM |

| Drive System | YASKAWA servo motors from Japan |

| Control System | Syntec CNC controller |

| Transmission Mechanism | XY axis: German WMH HERION rack and pinion; Z axis: Taiwan PMI ball screw |

| Worktable Surface | Vacuum table combined with T-slot design |

| Positioning Accuracy | ±0.03 mm per 300 mm |

| Repeatability Accuracy | ±0.05 mm |

| Machining Resolution | Finer than 0.01 mm |

| Z-Axis Calibration | Automatic tool height sensor for Z-axis origin setting |

| Lubrication System | Centralized oil lubrication |

| Supported File Formats | G-code, *uoo, *mmg, *plt |

| Compatible Software | UG (Unigraphics) |

| Power Requirements | AC 220V single phase / 380V three phase, 50/60 Hz |

| Operating Temperature | 0°C to 45°C |

| Operating Humidity Range | 30% to 75% relative humidity |